Pearl-2 fast-tracks UNL’s road safety tests

By Jennifer P

The blog post “Pearl-2 fast-tracks UNL’s road safety tests” by Epiphan delves into the essential role played by the Midwest Roadside Safety Facility (MwRSF) at the University of Nebraska-Lincoln (UNL) in advancing the field of roadside safety. Renowned globally for innovations like the Steel And Foam Energy Reduction (SAFER) barrier utilized by NASCAR, MwRSF is committed to making roads and highways safer for everyone who uses them.

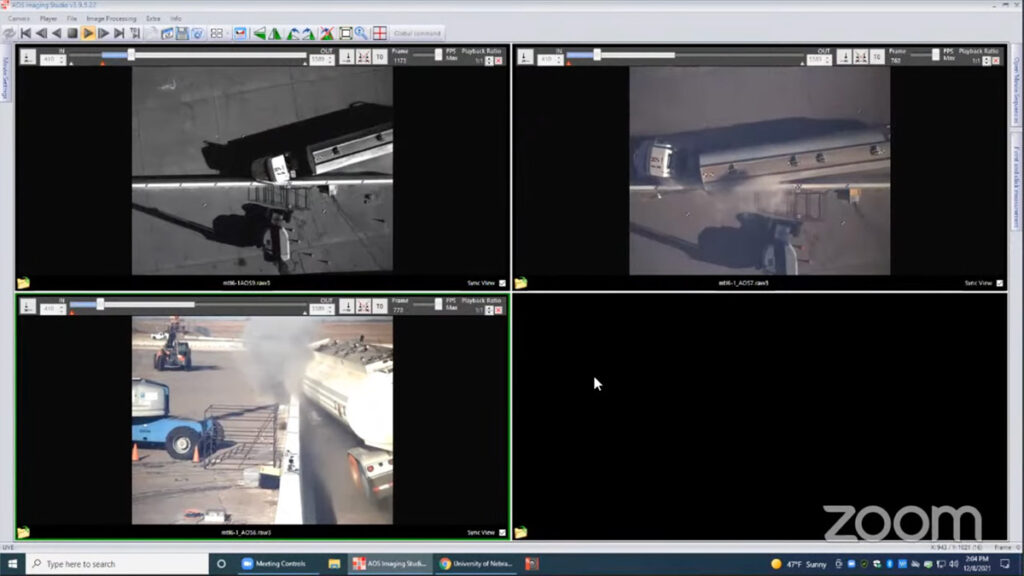

At the heart of MwRSF’s operations lies the meticulous process of designing and conducting tests for various roadside safety products. These tests involve high-speed crashes, and capturing every moment accurately is imperative for analysis. High-speed cameras are employed to record these tests, which often last only a few seconds in real-time. The video footage obtained during these tests is not just a tool but a cornerstone of research and learning, forming the basis for understanding impact dynamics and improving safety measures.

However, delivering this crucial video data in real-time posed significant challenges. With numerous stakeholders eagerly awaiting test results, the complex logistics of managing large, high-speed video files slowed down the process considerably. Remote stakeholders, including sponsors, engineers, and students, required immediate access to the footage to begin designing or adjusting subsequent tests. Additionally, the physical distance between the UNL campus and the test proving grounds, situated 12 miles apart, added another layer of logistical complexity.

Epiphan’s Pearl-2 emerged as a game-changer in MwRSF’s workflow, facilitating live streaming of crash tests and providing near-real-time feedback to stakeholders. This innovation allowed remote viewers to witness test events mere seconds after they occurred, bypassing the delays associated with physical file transfers. The live streams became platforms for real-time feedback and discussion, fostering seamless collaboration among stakeholders and enhancing the overall efficiency of the testing process.

One of the most significant advantages of integrating Pearl-2 was the substantial cost savings achieved by eliminating the need for stakeholders to attend crash tests in person. This was particularly beneficial for a non-profit organization like MwRSF, which operates within stringent budget constraints.

The transformative impact of Pearl-2 on MwRSF’s operations was evident in various aspects. Immediate access to test results empowered stakeholders to swiftly address challenges, accelerating problem-solving and expediting road safety enhancements. Furthermore, the saved travel costs further justified the investment in Epiphan’s equipment, aligning seamlessly with the financial considerations of a non-profit organization.

Test Site Manager and Research Associate Engineer at MwRSF, Jim Holloway, praised Pearl-2 for its reliability, user-friendliness, and versatility. He expressed excitement about exploring new applications and capabilities of Pearl-2, such as 4K workflows and low-latency streaming. Holloway’s enthusiasm reflects MwRSF’s ongoing commitment to refining testing methodologies and embracing technological innovations to advance roadside safety.

In conclusion, the integration of Pearl products marked a profound shift in MwRSF’s approach to roadside safety testing, setting a new standard for innovation in the field. Their dedication to exploring advanced workflows and leveraging Pearl’s capabilities underscores their commitment to enhancing safety measures for all road users. The significant cost savings achieved through the adoption of Epiphan’s equipment further reinforces its value and justifies its integration into MwRSF’s operations, aligning seamlessly with the financial considerations of a non-profit organization.

Read the full blog post from Epiphan HERE

Learn more about Epiphan Pearl 2 HERE

Learn more about Epiphan HERE